CHOCOLATE & CONFECTIONERY INDUSTRY

Applications

Emulsification: Lecithin acts as an emulsifier, helping to blend ingredients that don’t naturally mix well together, such as fats and water-based ingredients. This is particularly important in chocolate production, where lecithin ensures a smooth and homogeneous texture.

Texture Improvement: Lecithin helps improve the texture of confectionery products by contributing to their smoothness, creaminess, and overall mouthfeel. This is particularly important in chocolate production, where lecithin helps create a velvety and melt-in your-mouth texture.

Extended Shelf Life: Lecithin helps stabilize ingredients in confectionery products, which can extend their shelf life by preventing the separation of components and reducing the risk of oxidation.

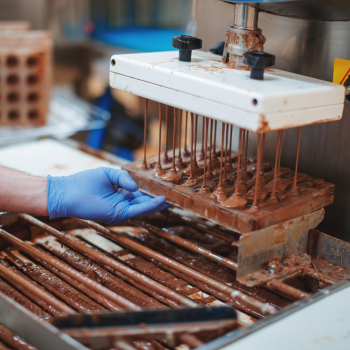

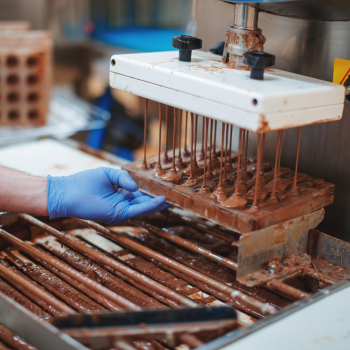

Reduced Viscosity: Lecithin can reduce the viscosity of chocolate and other confectionery coatings, making them easier to work with during production processes such as coating, dipping, and molding.

Improved Release Properties: Lecithin aids in the release of confectionery products from molds and equipment, ensuring smooth and clean demolding without sticking or residue.

Uniformity of Coatings: In chocolate and compound coatings, lecithin helps achieve a uniform and glossy finish by facilitating the dispersion of cocoa butter or other fats.

Clean Label Solutions: As a natural ingredient derived from plant sources, lecithin can be perceived as a clean label solution, meeting consumer preferences for natural and familiar ingredients.

Allergen Management: Lecithin derived from non-allergic sources, such as sunflower seeds, provides a viable option for confectionery manufacturers looking to manage allergen concerns related to soy based lecithin.